|

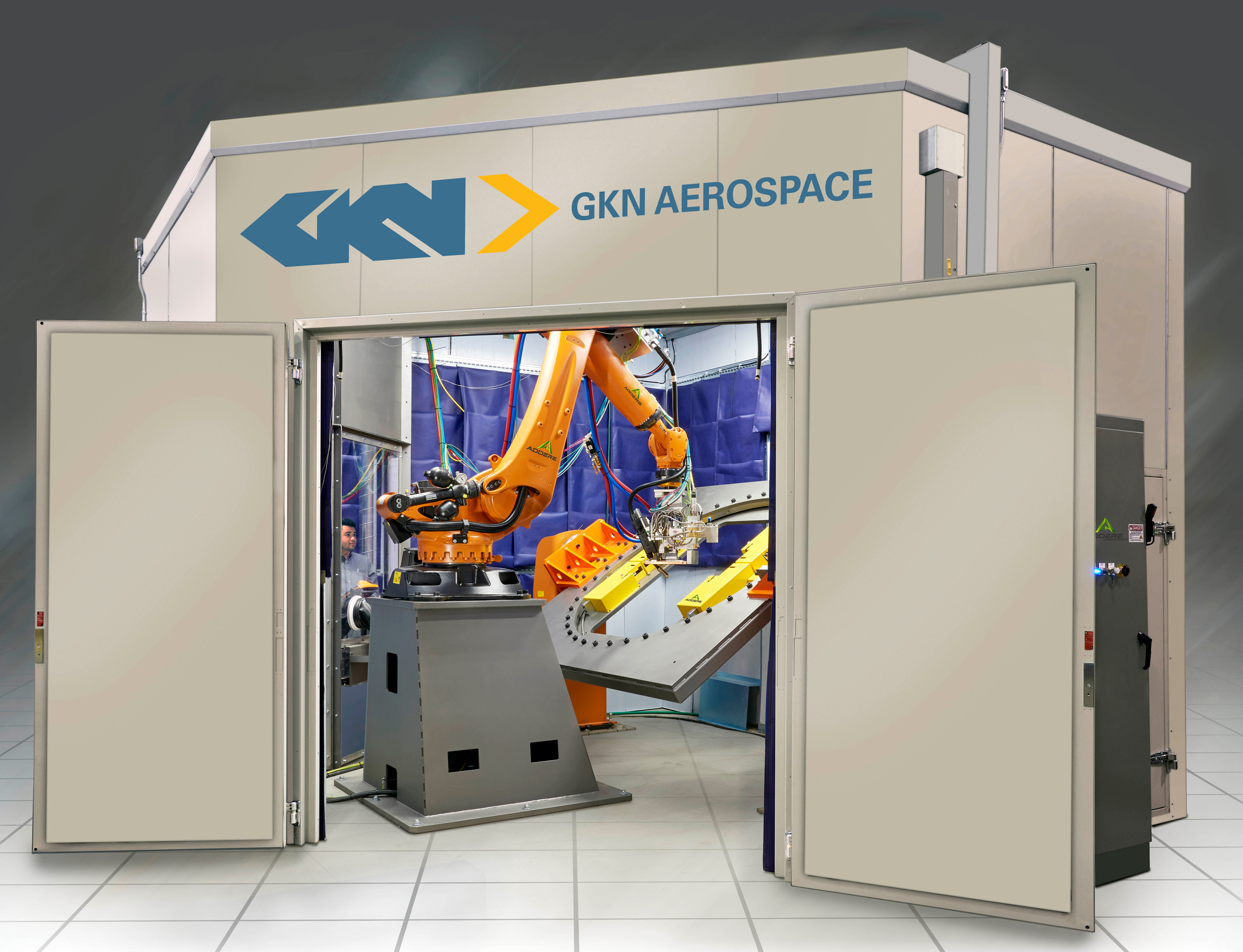

GKN Aerospace has opened a second additive

manufacturing cell (Cell 2) at the U.S. Department of Energy�s

(DOE) Oak Ridge National Laboratory (ORNL).

Located at the DOE�s Manufacturing Demonstration

Facility at ORNL, Cell 2 is the world�s largest pilot production

cell of its kind and is the next stage in GKN Aerospace�s additive

manufacturing research and development targeting large scale

structural aircraft components.

Mike McCann, CEO of GKN Aerospace�s

Aerostructures North America business said, �We are proud to

introduce the next step in our additive manufacturing research as

we continue to push the boundaries of this transformative

technology. We believe this to be the largest laser metal

deposition with wire (LMD-w) pilot production cell in the world.

With this, we will target large scale aerostructure components

with a focus on dramatic improvements in buy-to-fly and cost

reductions over plate and forgings.�

GKN Aerospace has been at the forefront of LMD-w

technology for more than a decade. This began at its aero-engine systems business based in

Sweden and, in 2017, GKN Aerospace expanded its LMD-w expertise

into large-scale aerostructures components by signing a five-year

US$17.8 million research agreement with ORNL.

�We are

extremely proud to strengthen our relationship with this

world-renowned laboratory to accelerate our progress towards fully

industrializing these processes for large-scale aerostructures

components. Through our cooperative research, we have seen

first-hand how additive manufacturing will continue to

revolutionize the design and manufacture of aircraft structures.

This cell will allow us to create complex components without

compromising performance,� said McCann.

The 2017 agreement

included the opening of GKN Aerospace�s first prototype cell at

ORNL which, over the past two years, has transitioned technology

from GKN Aerospace engines to aerostructures applications and

implemented advanced closed-looped controls to manage the process

with complex geometry. Cell 2 helps accelerate this work in the US.

The GKN Aerospace Cell 2 features include:

*

20KW laser

* 8-axis of motion

* Large area inert enviroment

* 52in x 32in max substrate size

* Two-sided deposition

Cell 2 is a pilot production cell designed to enable full

industrialization of the LMD-w process for aerostructures

components. Some applications will include: product development,

low-rate initial production and the transition of technology

development into production solutions.

�Our research

collaboration with GKN Aerospace demonstrates the rapid progress

that can be made when industry and the national labs work hand in

hand,� said Moe Khaleel, associate laboratory director for Energy

and Environmental Sciences at ORNL. �We are pleased to see our

relationship with GKN expand, and look forward to continued

technological innovation in our mission to translate science into

solutions for advanced manufacturing.�

GKN Aerospace

already has additive manufacturing components flying on seven

different major platforms today, across the commercial, military,

rotorcraft, business jets and space markets.

|

Headlines: |

|

See latest

HD Video

Interviews,

Podcasts

and other

news regarding:

GKN,

Additive.

|