|

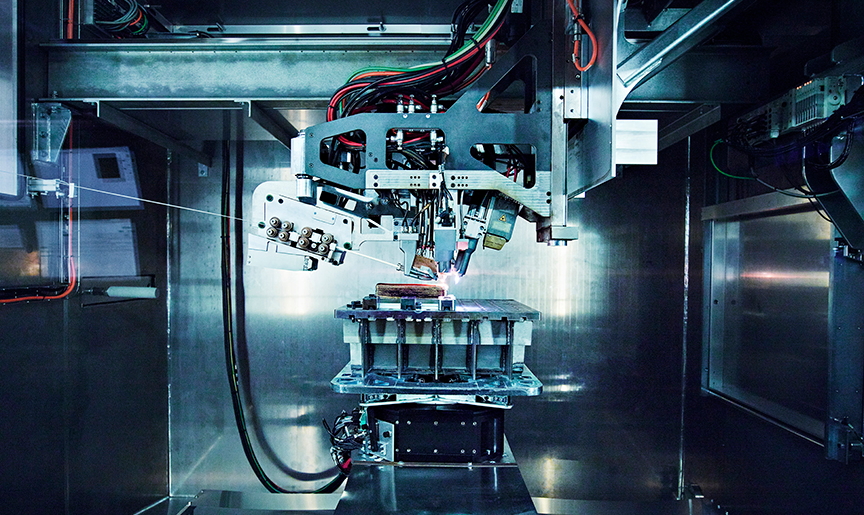

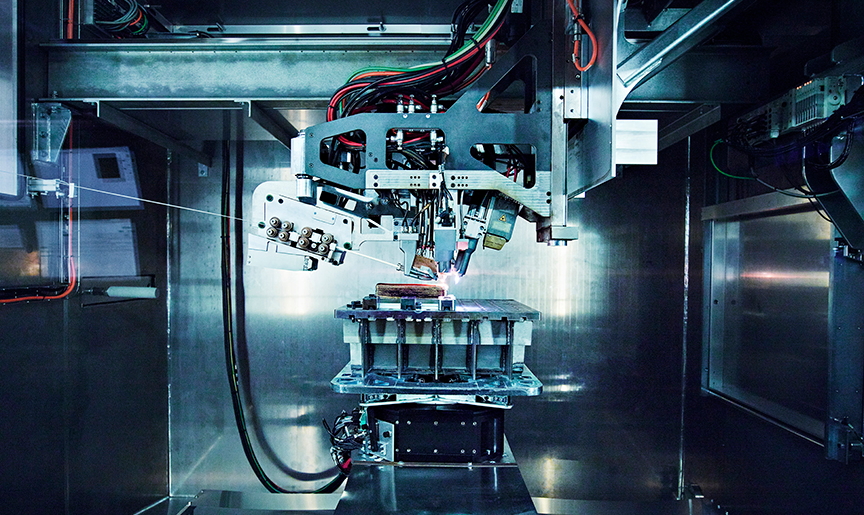

Norsk Titanium has received a production

purchase order from Boeing for 3D-printed structural titanium

components that are being produced by Norsk�s proprietary Rapid Plasma

Deposition (RPD) process.

�We are proud to take this

historical step with a great aerospace innovator like Boeing,�

said Norsk Titanium President & Chief Executive Officer Warren M. Boley, Jr. �The Norsk Titanium team will continue to expand the

portfolio of components supplied to Boeing meeting stringent

certification requirements. It is an honor to earn FAA approval

for these structural parts.�

Boeing designed the components

and collaborated closely with Norsk Titanium throughout the

development process. To certify these initial structural

components on the Dreamliner, Boeing and Norsk Titanium undertook

a rigorous testing program with FAA certification deliverables

completed in February 2017.

Norsk Titanium, with their wire-based

RPD process, is the first supplier for Boeing�s high deposition

rate material specification.

�From the outset, the 787 has

been the hallmark of innovation and efficiency,� said John Byrne,

vice president, Airplane Materials and Structures, Supplier

Management, Boeing Commercial Airplanes. �We are always looking at

the latest technologies to drive cost reduction, performance and

value to our customers and Norsk Titanium�s RPD capability fits

the bill in a new and creative way.�

The Dreamliner RPD

components will be on display at the International Paris Airshow,

Le Bourget 19-25 June 2017 at Norsk Titanium�s booth in Hall 1,

Space H299, along with a full-scale mock-up of the company�s

patented Merke IV Rapid Plasma Deposition machine that produced

the pioneering structural parts.

|

Headlines: |

|

See latest

HD Video

Interviews,

Podcasts

and other

news regarding:

Boeing,

Dreamliner,

787,

Norsk,

Titanium.

|